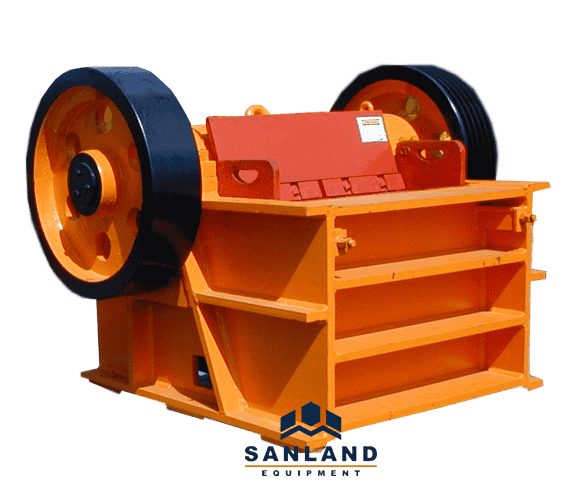

At the heart of their functionality lies the swing jaw’s rhythmic motion, moving back and forth against a fixed jaw. This action creates intense compression forces, effortlessly crushing material down to the desired size.

KEY FEATURES

Primary Crushing Prowess: These crushers are adeptly suited for primary crushing tasks, laying a solid foundation for subsequent processing stages.

Generous Feed Sizes: Their design accommodates large feed sizes, ensuring smooth and continuous operations.

Impressive Production Rates: With their robust construction and efficient mechanisms, they guarantee a high production rate, keeping up with the demanding pace of heavy industries.

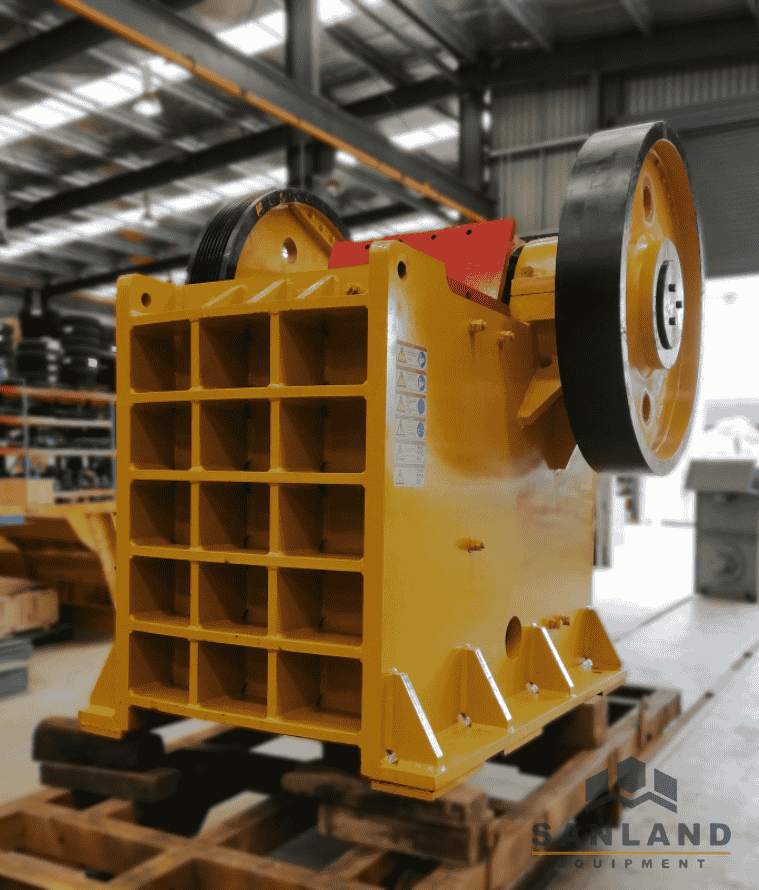

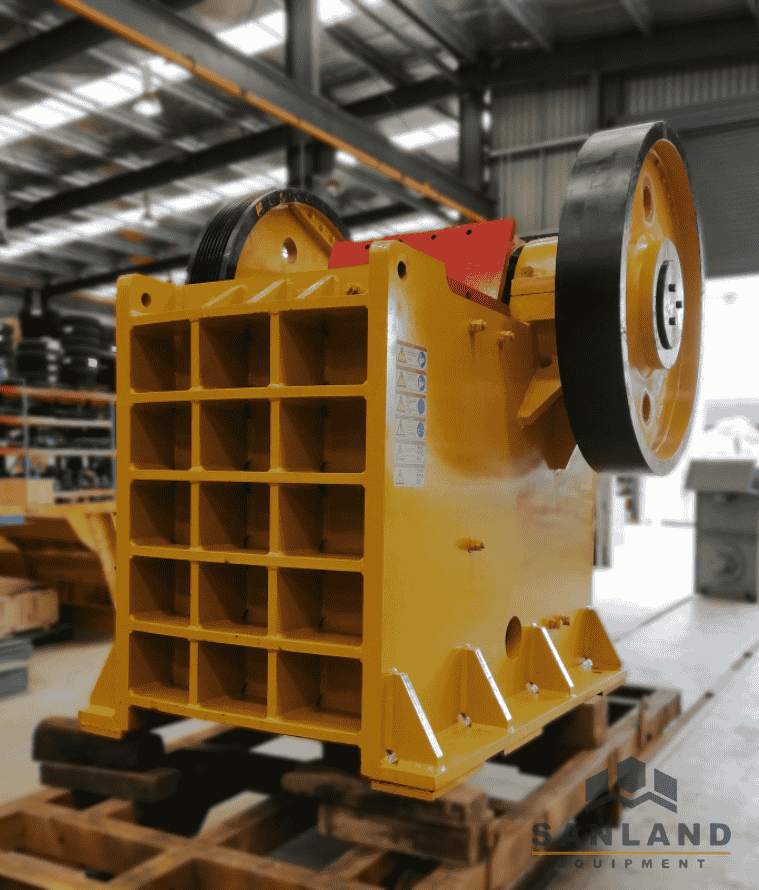

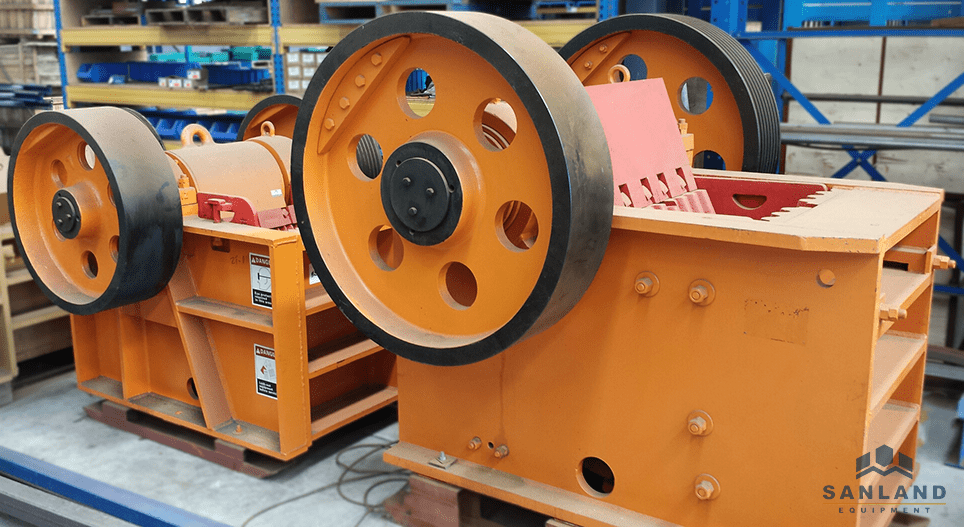

Sanland Equipment offers a range of static jaw crushers, from standalone units to custom-built plants. Our portfolio includes designs that cater to a variety of needs, making them perfect for diverse applications. For those prioritizing adaptability and efficiency, our modular jaw crushers ensure swift installation and scalable performance. And for clients who need mobility in their operations, we proudly offer a lineup of tracked mobile jaw crushers.

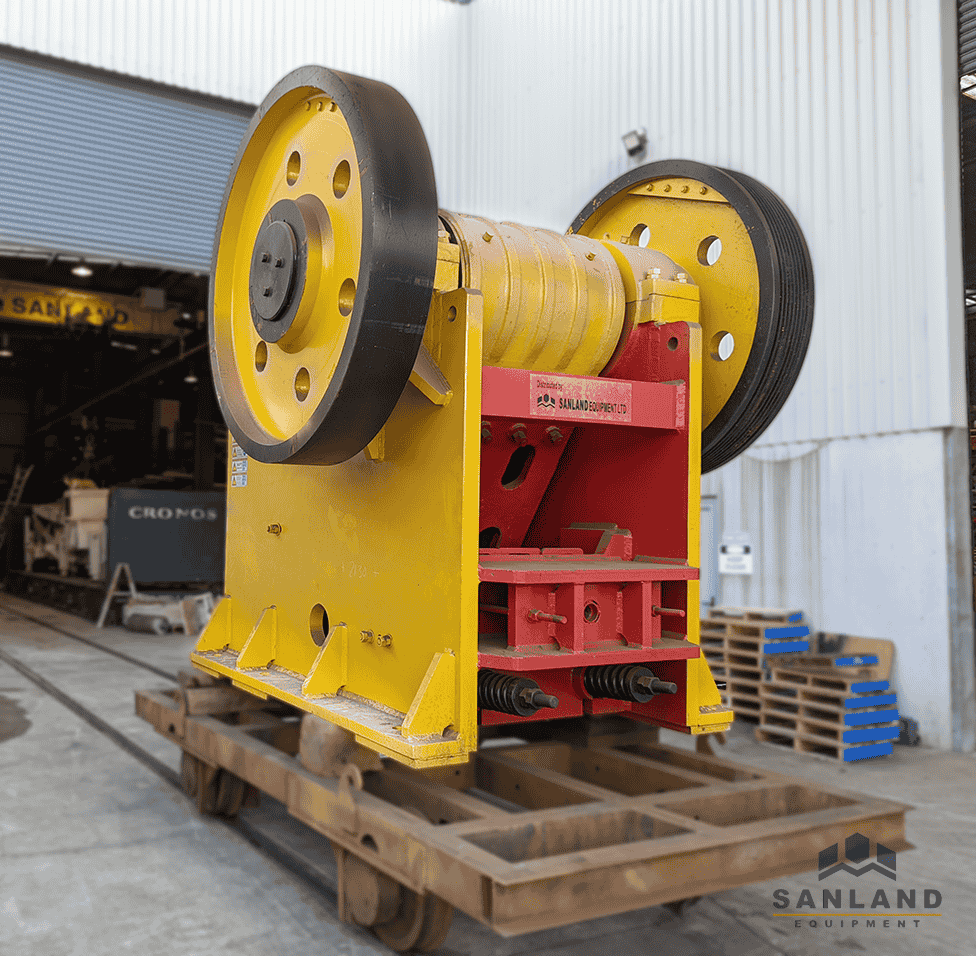

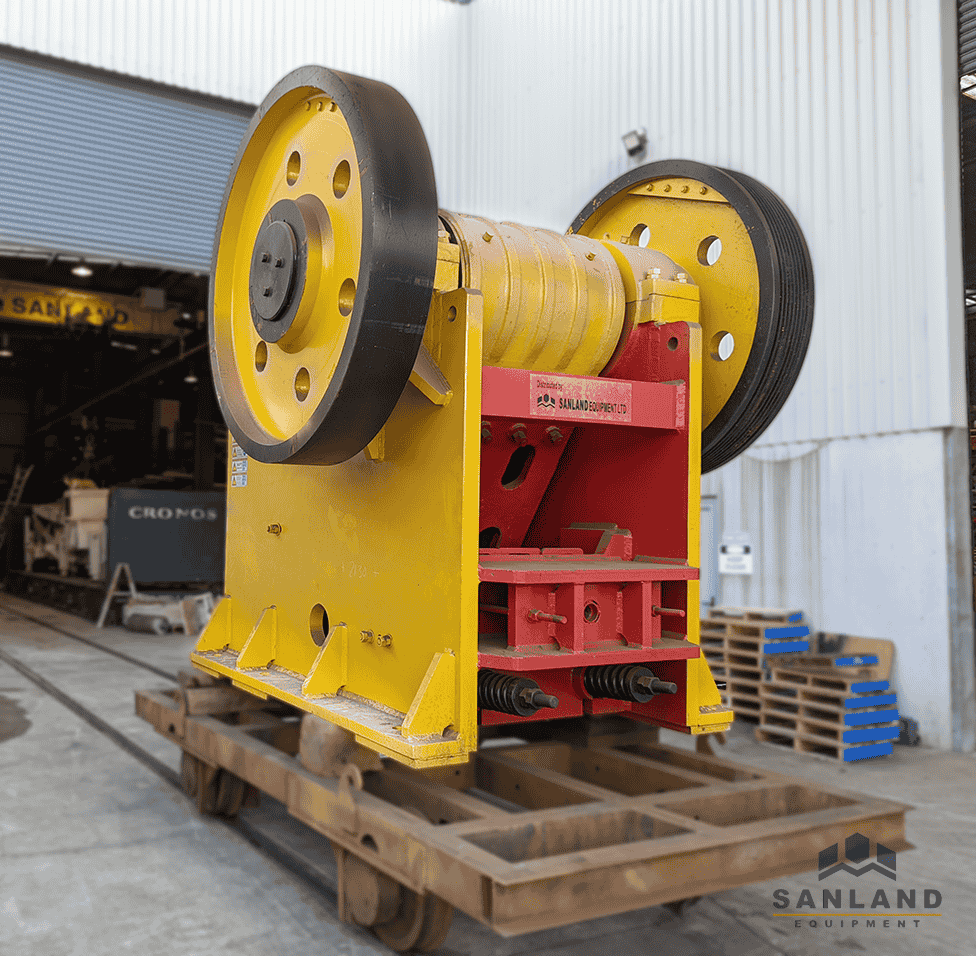

The advantage of our static jaw crushers is evident in their construction: without the weight constraints typical of tracked machines, they’re built using substantially thicker forged steel. This sturdiness not only ensures they withstand the toughest crushing tasks but also grants them longevity. In fact, with meticulous maintenance, Sanland jaw crushers can serve reliably for an entire generation, making them a wise investment for those seeking enduring performance.

| Model of machine | Feed Opening In (MM) | recommended Max feed size | Range of discharge opening (MM) | Crushing capacity (tph) | Motor power (kw) |

|---|---|---|---|---|---|

| SEJ | 250 x 400 | 210 | 20 - 60 | 5 - 21 | 15 |

| SEJ | 400 x 600 | 340 | 40 - 100 | 16 - 64 | 30 |

| SEJ | 500 x 750 | 425 | 50 - 100 | 45 - 100 | 55 |

| SEJ | 600 x 900 | 500 | 65 - 160 | 48 - 120 | 55 / 75 |

| SEJ | 750 x 1060 | 630 | 80 - 140 | 115 - 208 | 110 |

| SEJ | 1000 x 1200 | 850 | 195 - 265 | 315 - 342 | 132 |

| SEJ | 1200 x 1500 | 1020 | 150 - 350 | 300 - 800 | 220 |

| SEJ | 1500 x 1800 | 1200 | 220-350 | 450 - 1000 | 355 |

A jaw crusher with a wider and shallower jaw can be referred to as a granulator. They are also commonly used for secondary and tertiary crushing as they can produce a relatively smaller material size while maintaining an impressive output.

| Model of machine | Feed Opening In (MM) | recommended Max feed size | Range of discharge opening (MM) | Crushing capacity (tph) | Motor power (kw) |

|---|---|---|---|---|---|

| SEJ | 250 x 1000 | 210 | 25 - 60 | 16 - 52 | 30 / 37 |

| SEJ | 250 x 1200 | 210 | 25 - 60 | 20 - 60 | 37 |

| SEJ | 300 x 1300 | 210 | 20 - 90 | 20 - 144 | 75 |

Contact us so we can discuss how our solutions can be tailored for your experience

81 Boundary Road Papakura, Auckland, New Zealand

09 296 9488