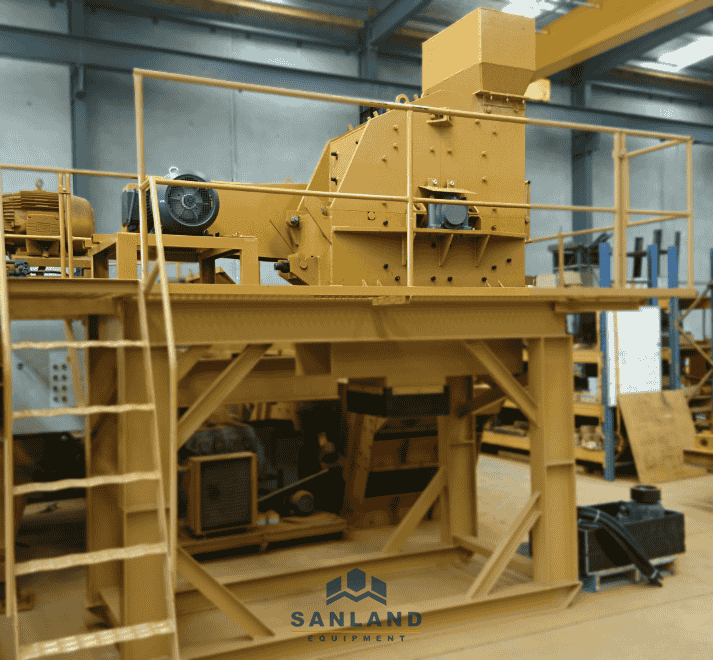

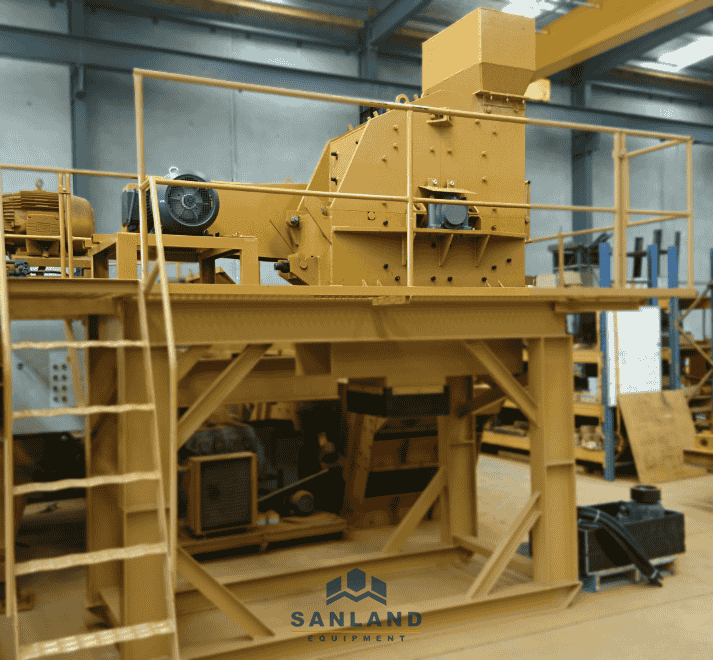

Setting the Standard for Horizontal Shaft Impact Crushing:

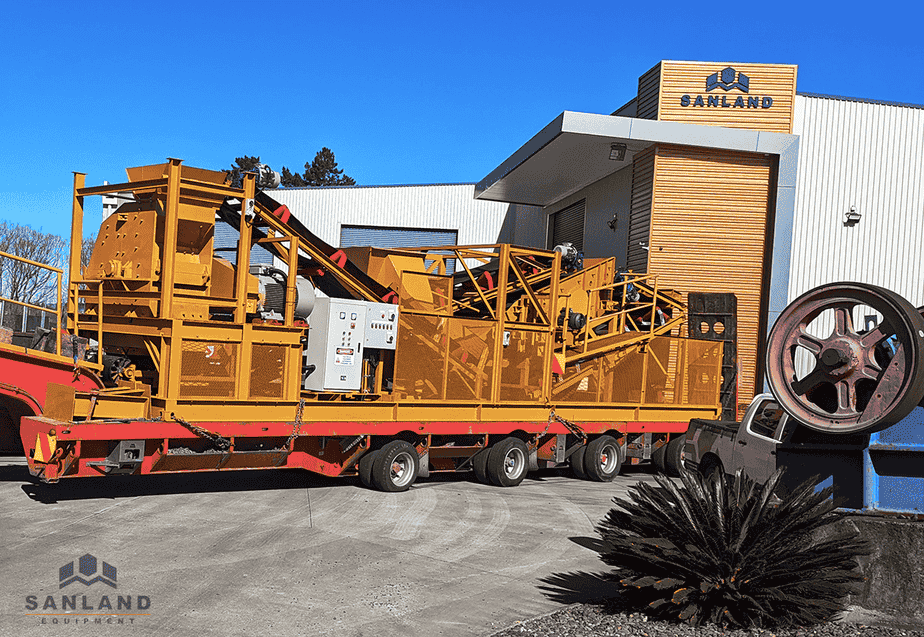

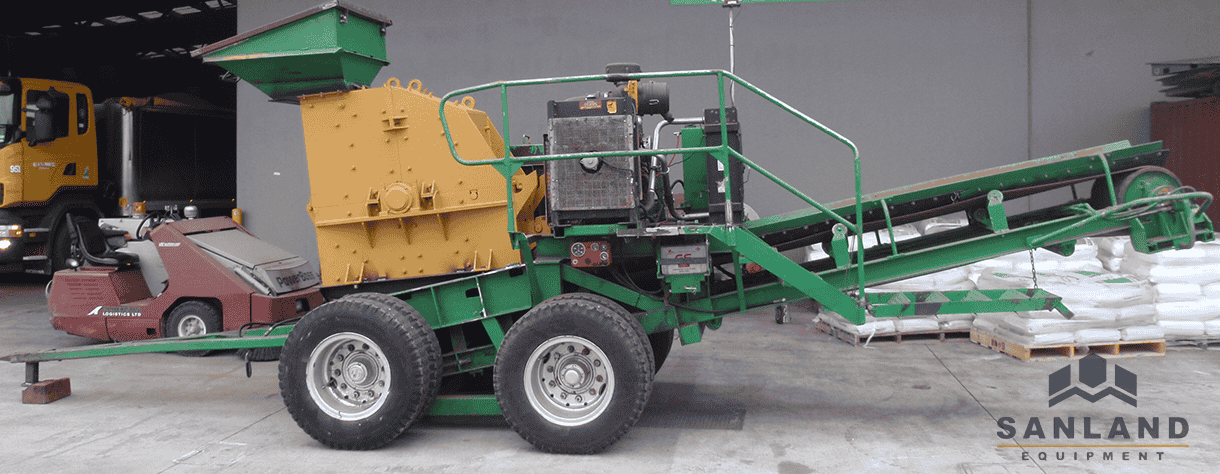

Currently our region’s most popular crushing machine model and continuing to gain further recognition across New Zealand, Australia, and the Pacific Islands, the Kumbee Hammermill stands as a testament to versatility. While it’s a darling of the quarrying sector, producing cubical aggregates paramount for construction, its prowess extends to the mining industry, expertly fragmenting ore to unveil the valuable minerals encased. The Kumbee hammermill has also seen success in other industries such as agricultural feed processing and glass recycling.

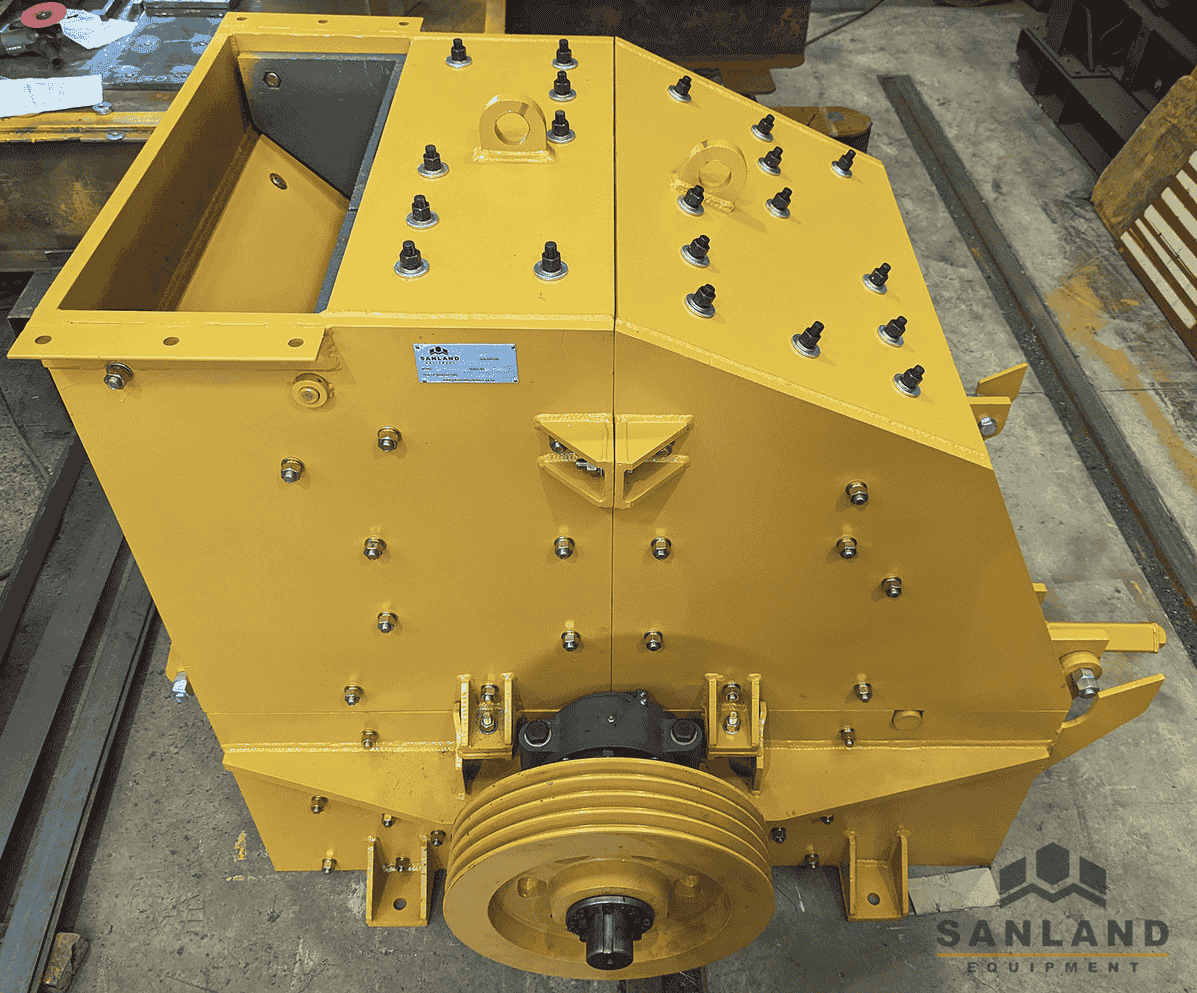

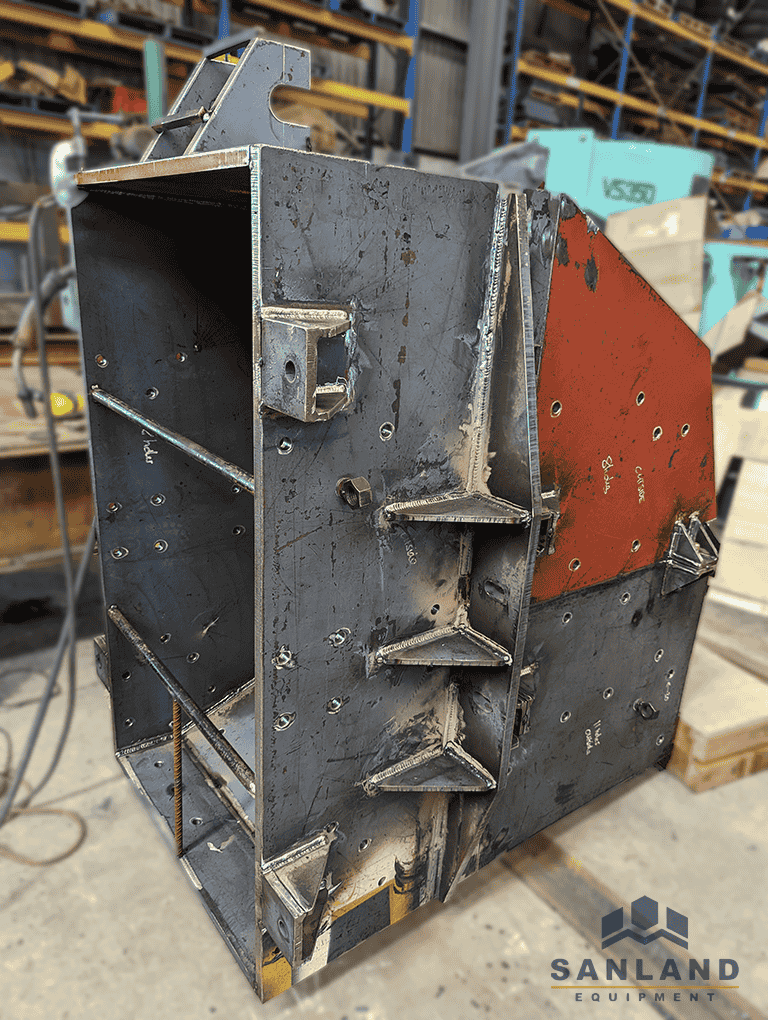

What sets it apart? The Kumbee Hammermill produces perfectly cubed products, adeptly filtering out soft stone. Even materials that usually jam other equipment are effortlessly processed, thanks to its unique design that ensures significant stone and gravel interaction with the breaker plates, clearing any build-up. For those seeking diverse output, our hammermill can be tuned to produce a rich mix of sand and dust.

Notable Features:

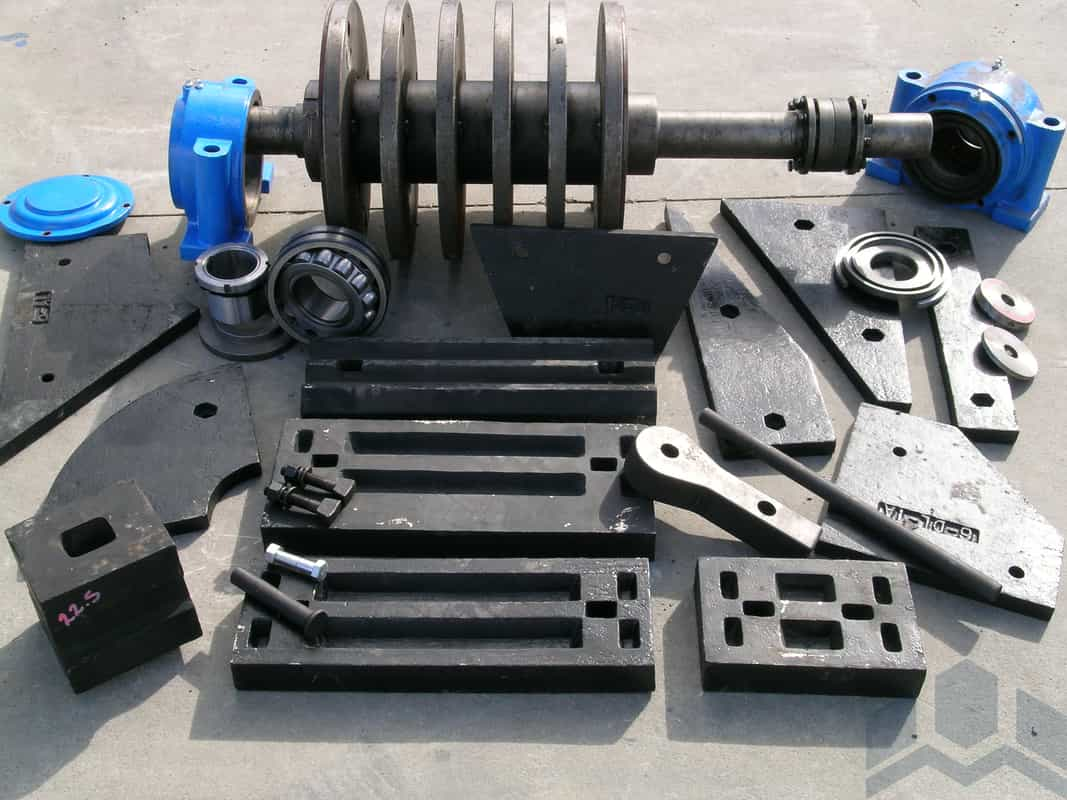

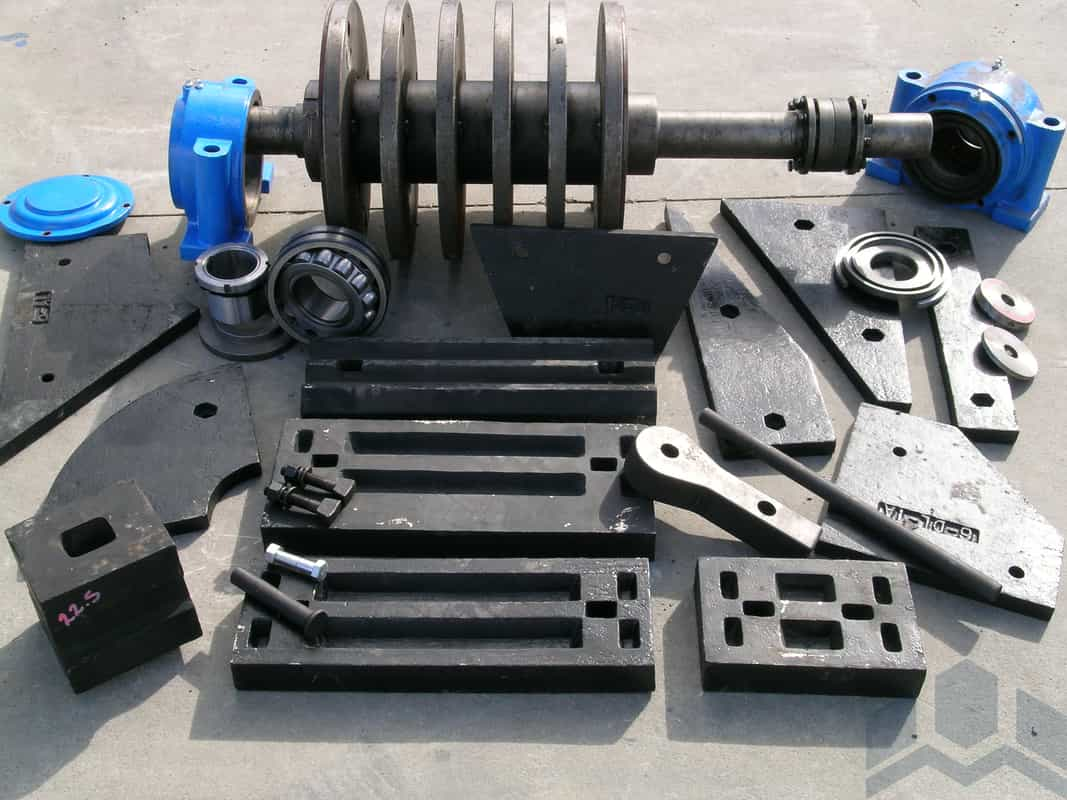

Embrace the excellence of Kumbee Hammermill, where innovation meets durability. The Kumbee Hammermill is built right here in our workshop in Auckland. Available in sizes 1 and 1.5, along with its sister machine the A&B Hammermill/Lime mill. Our Kumbee 1 and 1.5 is also designed to have mostly common and interchangeable wear parts.

| Type | Kumbee 1 | Kumbee 1.5 |

|---|---|---|

| Max feed size | 125 mm | 125 mm |

| Feed Opening | 550 x 312 mm | 830 x 410 mm |

| Length | 1840 mm | 1840 mm |

| Width Over Shaft | 1296 mm | 1585 mm |

| Width over Frame | 626 mm | 880 mm |

| Height | 1613 mm | 1613 mm |

| RPM | 600 / 900 | 600 / 900 |

| Power Requirement | 25 - 37 kw | 50 - 80 kw |

| Machine Weight | 4,000 kg | 5,000 kg |

| Production rate (hard rock) | ~50 tph | ~75 tph |

Contact us so we can discuss how our solutions can be tailored for your experience

81 Boundary Road Papakura, Auckland, New Zealand

09 296 9488