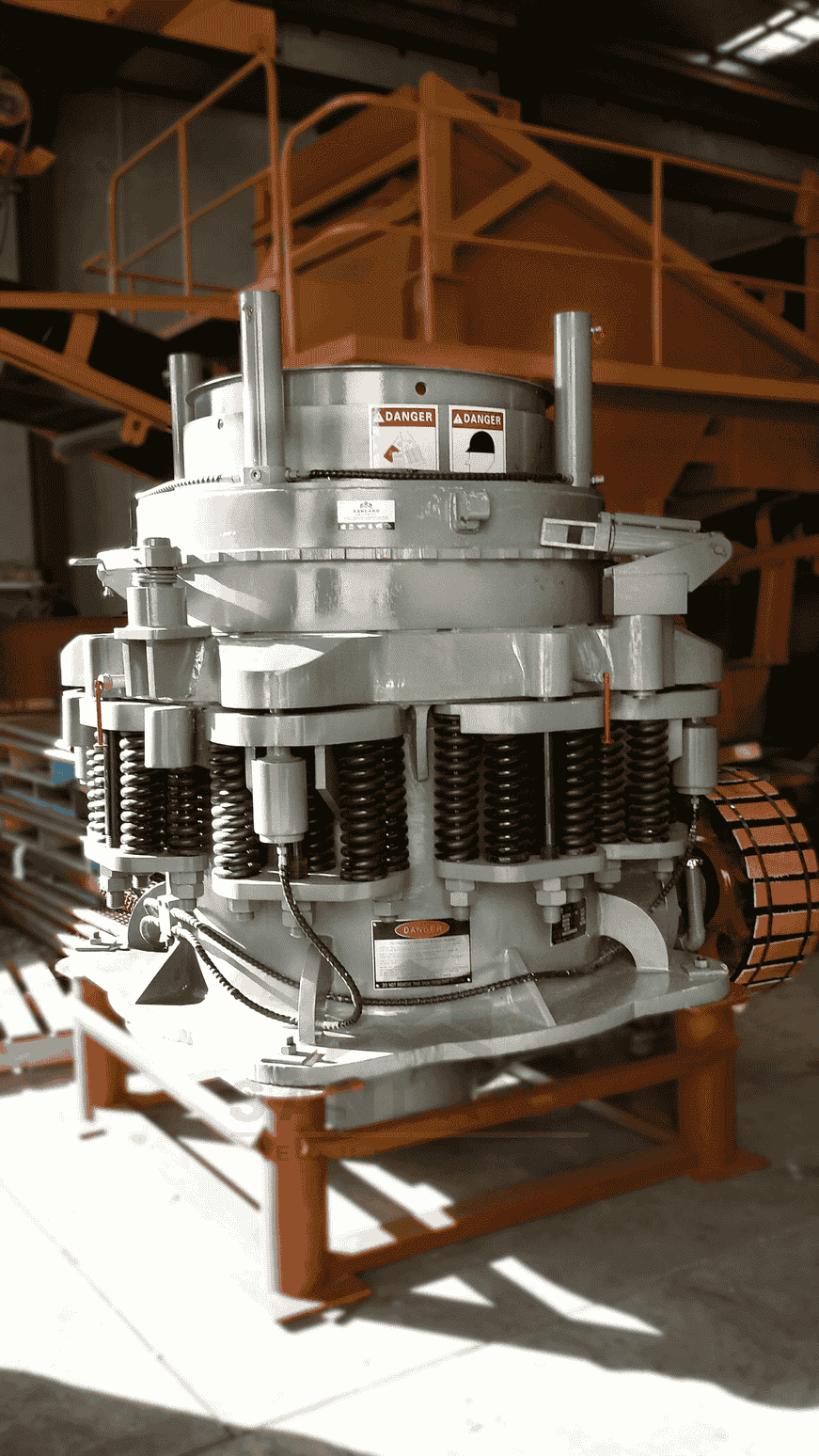

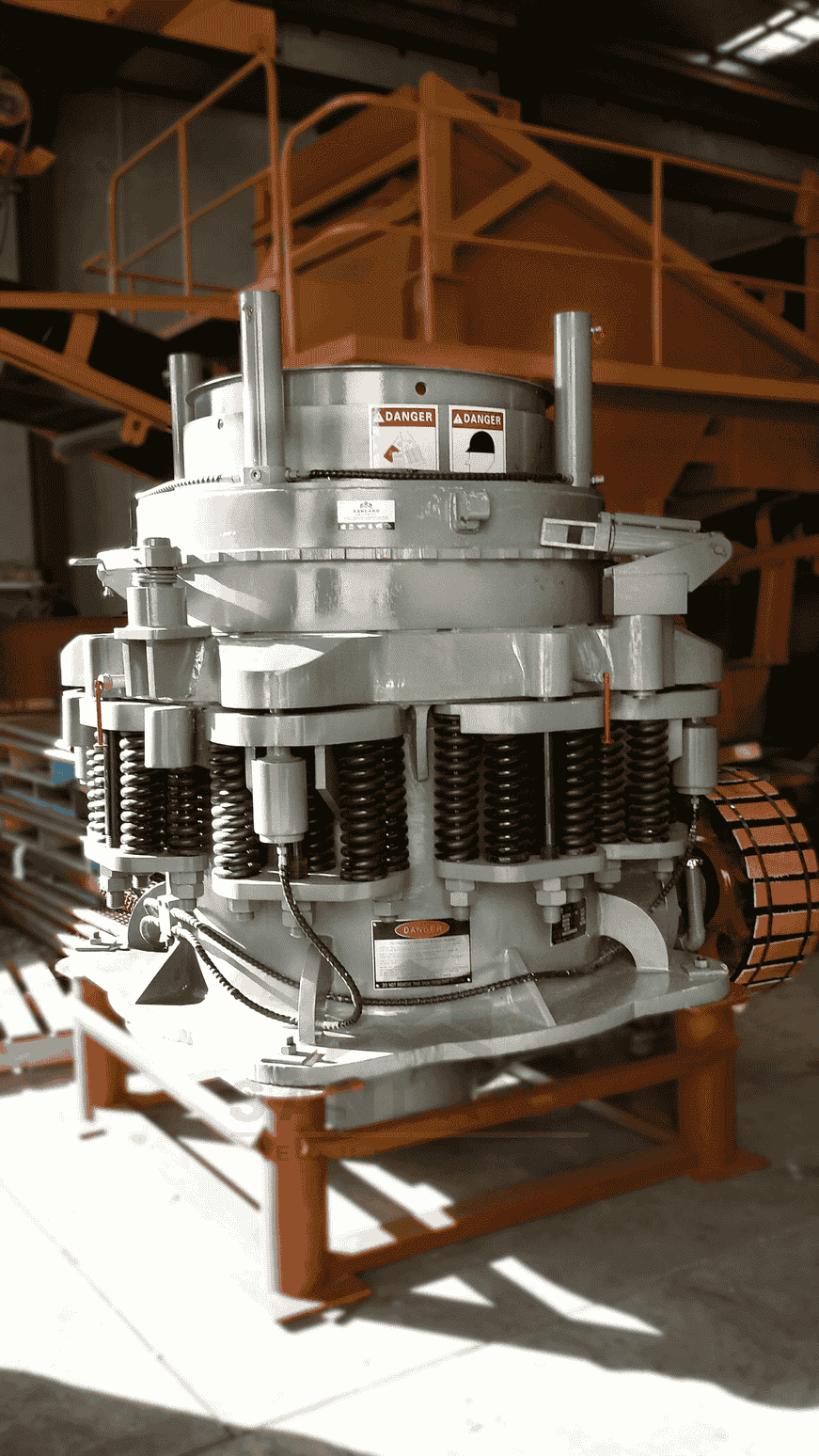

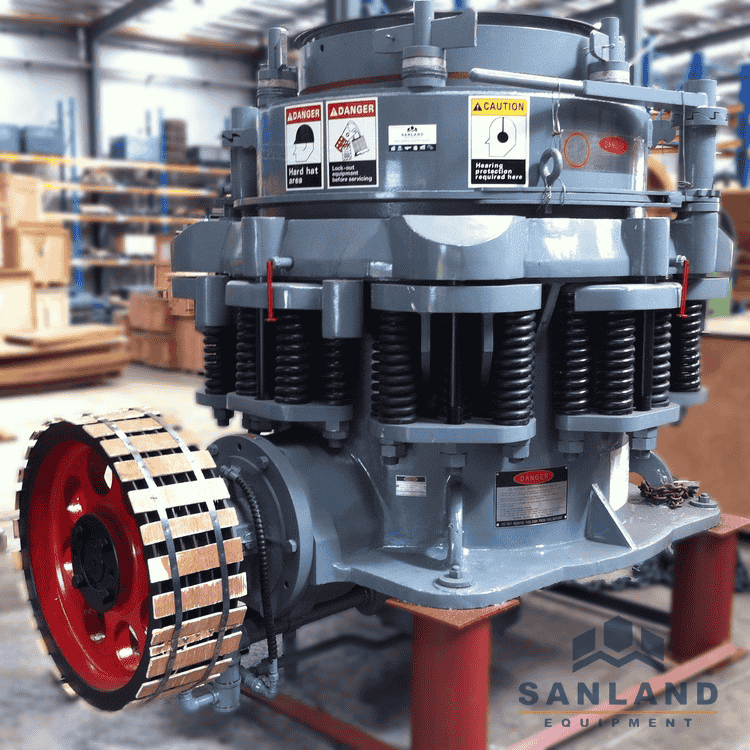

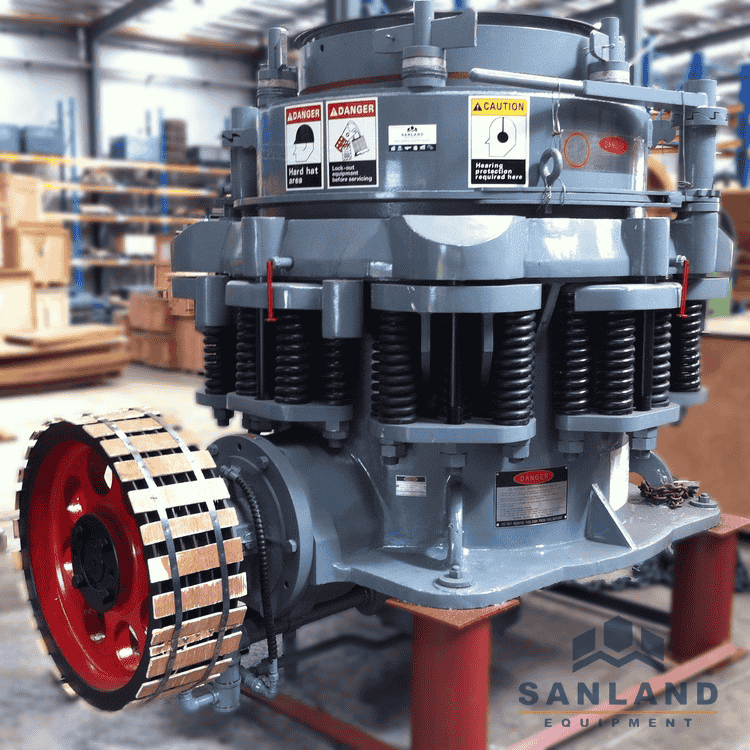

Sanland Equipment offers a range of static cone crushers, from standalone units to custom-built plants. Our portfolio includes the renowned Symons design and other cone crusher types, perfect for diverse applications. For those seeking adaptability with efficiency, our modular solutions ensure quick installation and scalable performance.

Dipping into a legacy that has stood the test of time, the Symons static cone crusher offers an unsurpassed crushing experience, now enriched with modern enhancements. Central to its design is the Hydraulic tramp clearance – a feature that ensures obstruction-free operation by effortlessly releasing any uncrushable materials that might find their way between the mantle and the crusher bowl.

Complementing this is the fully automatic packaged lubricating oil system, with temperature sensors and built-in fail safes, it ensures that the crusher’s lubrication is always running optimally.

| Size | Cavity type | recommended Max feed size | Close-side setting range | Crushing capacity (tph) |

|---|---|---|---|---|

| 3 ft (914 mm) | Fine | 82 mm | 9 - 22 mm | 50 - 100 tph |

| 3 ft (914 mm) | Coarse | 140 mm | 13 - 38 mm | 65 - 180 tph |

| 3 ft (914 mm) | Extra Coarse | 144 mm | 25 - 38 mm | 130 - 180 tph |

| 4 1/4 ft (1295 mm) | Fine | 110 mm | 13 - 31 mm | 120 - 200 tph |

| 4 1/4 ft (1295 mm) | Medium | 170 mm | 16 - 38 mm | 145 - 280 tph |

| 4 1/4 ft (1295 mm) | Coarse | 193 mm | 19 - 51 mm | 190 - 385 tph |

| 4 1/4 ft (1295 mm) | Extra Coarse | 207 mm | 25 - 51 mm | 260 - 395 tph |

| 5 1/2 ft (1676 mm) | Fine | 167 mm | 16 - 38 mm | 200 - 360 tph |

| 5 1/2 ft (1676 mm) | Medium | 193 mm | 22 - 51 mm | 285 - 460 tph |

| 5 1/2 ft (1676 mm) | Coarse | 215 mm | 25 - 61 mm | 330 - 700 tph |

| 5 1/2 ft (1676 mm) | Extra Coarse | 295 mm | 38 - 64 mm | 574 - 750 tph |

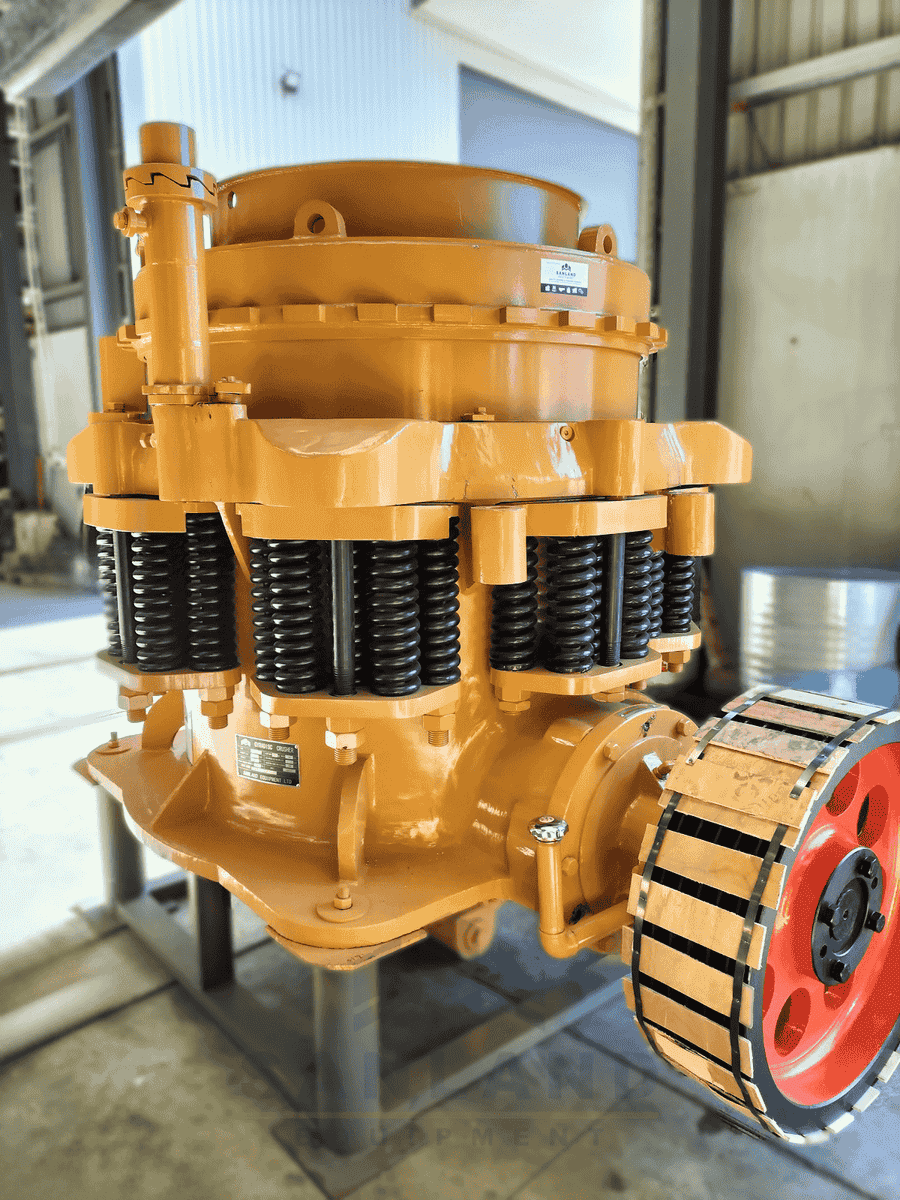

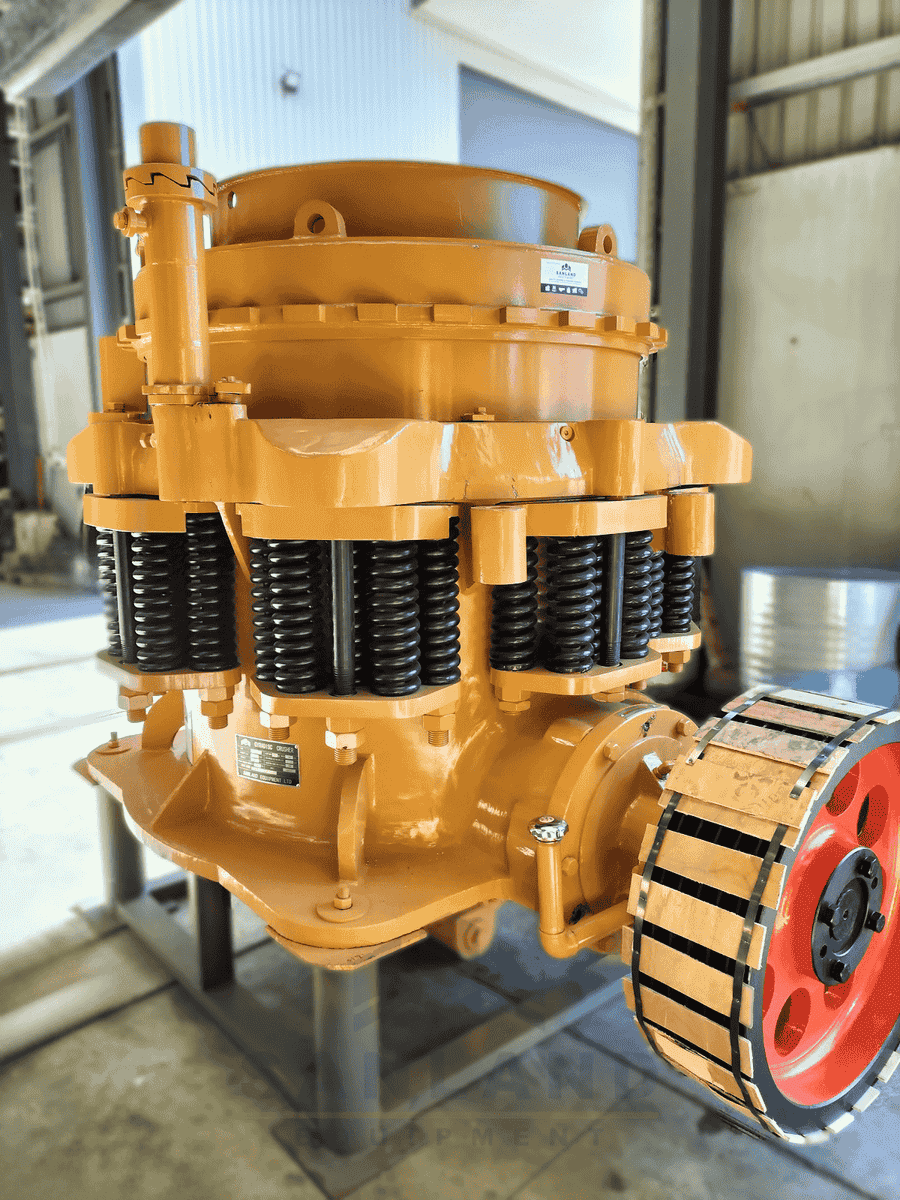

The Symons Gyradisc Cone Crusher, designed primarily for fine or tertiary crushing, stands out in its capability to produce fine particle sizes, making it particularly valuable for producing sand and other fine aggregates.

Distinguished by its shallower crushing angle and longer parallel zone between crushing zones, the Gyradisc crusher’s design ensures the production of a more cubical and evenly-shaped product, which is highly sought-after in modern applications, especially for crafting concrete and asphalt aggregates. Although it features a smaller feed opening compared to standard cone crushers, its specialized design means it might offer fewer adjustment options, but its precision in output is unparalleled.

The Gyradisc crusher, therefore, is an excellent choice when the focus is on product granularity and shape.

While the Symons standard cone crusher is more versatile in its application and can handle larger feed sizes, the Gyradisc crusher is specialized for producing finer, more uniform output. When choosing between the two, it’s essential to consider the desired output size, shape, and application.

Contact us so we can discuss how our solutions can be tailored for your experience

81 Boundary Road Papakura, Auckland, New Zealand

09 296 9488