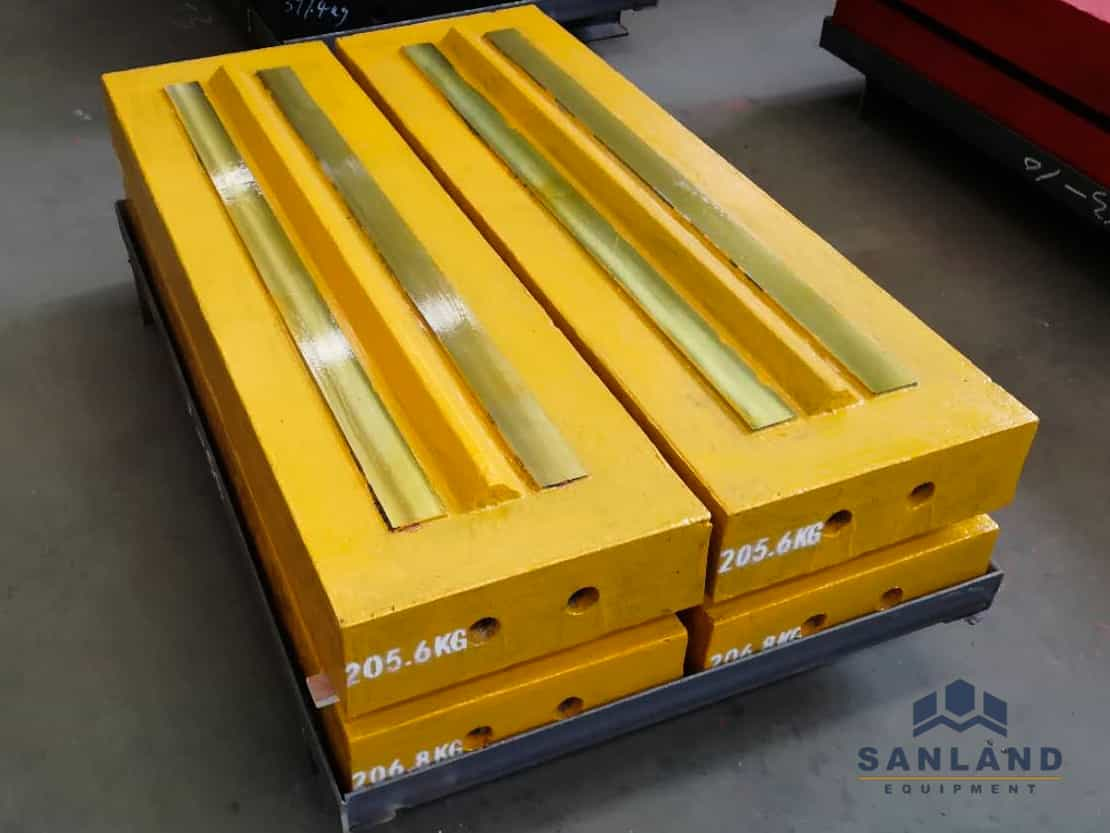

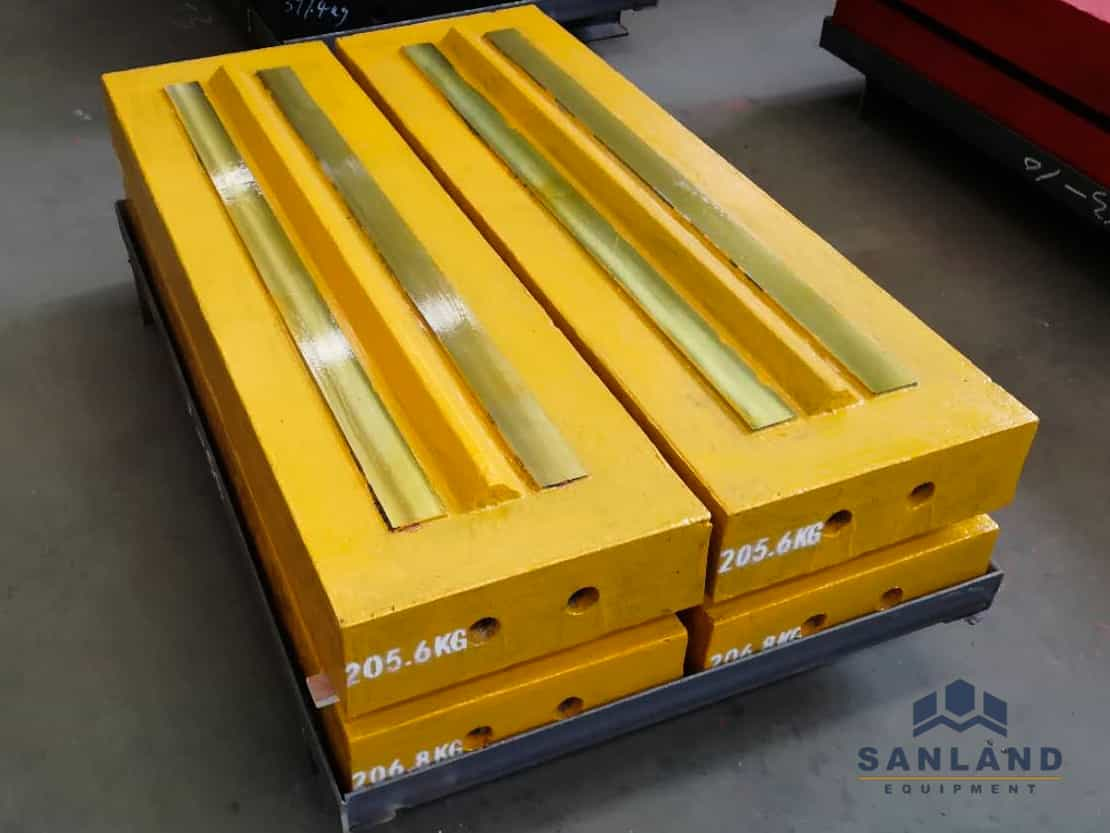

We recognise that impactors, especially when dealing with abrasive aggregates, can experience extensive wear. Often, the cost of wear parts can significantly influence production expenses.

Depending on your application’s specific demands, we offer a diverse range of hammer/blow bar compositions. From high manganese to high chrome, and even to more advanced materials like high chrome ceramic and ceramic matrix composite. It’s essential to note, however, that while higher abrasion resistance can lead to more extended wear life, these very properties can render the wear parts more brittle. This makes them susceptible to potential failures when oversized or foreign metal objects are introduced.

Balancing wear rate, cost, and hardness can be challenging, but we’re here to guide you in making the optimal selection. Our partnership with leading foundries places us at the forefront, enabling the development of top-tier impactor wear parts, crafted using innovative manufacturing techniques and the finest materials.

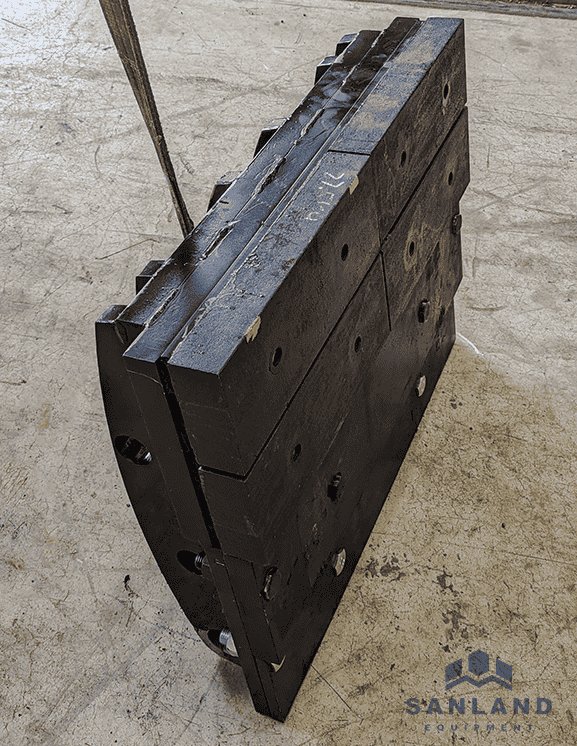

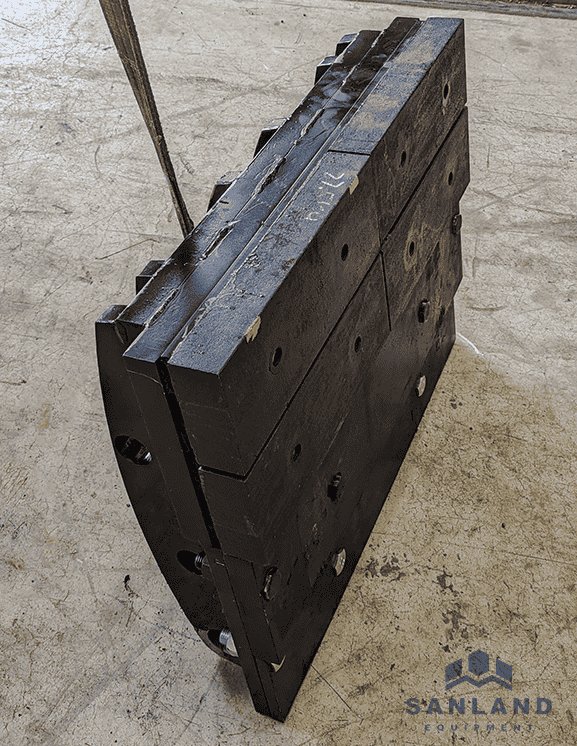

Entire rotor assemblies available for certain models.

The product brands mentioned on our website or in any of our marketing materials are only references to Original Equipment Manufacturer (OEM) manufacturers.

Unless specified, we have no association with these manufacturers. We supply aftermarket products that are compatible with the machines manufactured by these OEMs.

Any use of these product brands, trademarks, or model names on our website or in our marketing materials is solely for the purpose of identifying the machines our products are compatible with

Contact us so we can discuss how our solutions can be tailored for your experience

81 Boundary Road Papakura, Auckland, New Zealand

09 296 9488